Fluon HR-930 is a high-flow specially designed low-melting copolymer of ethylene and tetrafluoroethylene that delivers superior thermal stability when compared to standard ETFE materials.

The characteristics of Fluon®ETFE provide the superior solution, in terms of cost reduction compared to the use of other fluoropolymers, or improved performance if replacing conventional materials.

Fuctions and Features

Extrusion, injection molding and powder coating using ETFE are generally possible, similar to general thermoplastic resins, leaving the inherent characteristics of fluoropolymers unchanged. Filming, heat-sealing, composition with rubber and various secondary processes are also possible.

Stable mechanical electrical properties are maintained over a wide range of temperatures, -200 - +180°C. Continuous service at 150°C is possible.

It exhibits outstanding chemical resistance to nearly all chemical substances, including strongly-acidic and strongly-alkaline substances.

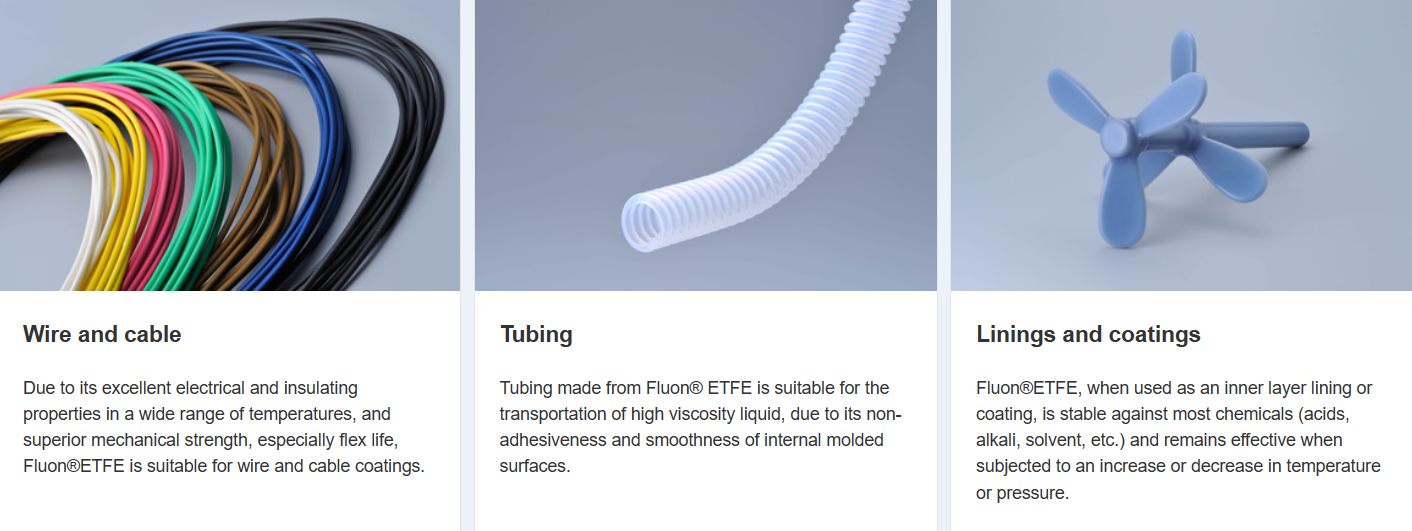

Usage:

Fluon HR-930 is a high-flow specially designed low-melting copolymer of ethylene and tetrafluoroethylene that delivers superior thermal stability when compared to standard ETFE materials.

Fluon HR-930 can be processed using conventional thermoplastics techniques such as extrusion and injection molding. This product is available as an 1/8” pellet.

Contact: Lily Chan

Phone: 86-13712404698

E-mail: lily@hopskip-jump.com

Whatsapp:86-13712404698

Add: Room 1601, Unit 2, Building 1, Wanhui Centre, No.72 GuanZhang Road, Dongguan, GuangDong, China

We chat